CGDS

( Centeralzed Gas Pipline System )

Centralized Gas Distribution System (CGDS)

Safe. Efficient. Modern.

Welcome to the future of gas management with our Centralized Gas Distribution System (CGDS) — a smart, streamlined solution designed to distribute medical gases efficiently, safely, and without interruption.

Whether you’re running a multi-specialty hospital or a research laboratory CGDS ensures that the supply of essential gases remains uninterrupted, secure, and completely under control.

What is a Centralized Gas Distribution System?

A Centralized Gas Distribution System (CGDS) is an integrated network that supplies medical or industrial gases (like oxygen, nitrous oxide, carbon dioxide, nitrogen, etc.) from a central storage area directly to various end-use points across a facility. Instead of relying on separate cylinders for each room or department, CGDS centralizes the storage and manages distribution via pipelines, manifolds, regulators, alarms, and valves. This drastically reduces the risks of leakage, improves efficiency, and ensures a 24/7 uninterrupted gas supply.

Where is CGDS Used?

Our CGDS solutions are perfectly suited for:

Hospitals & Healthcare Centers

For distributing medical-grade oxygen, nitrous oxide, vacuum, and other life-supporting gases to operating theaters, ICUs, wards, and labs.

Research Laboratories

Ensuring pure gas delivery to analytical devices and research setups.

Key Benefits of Choosing CGDS

Say goodbye to manual cylinder handling and potential leakage risks. CGDS keeps gases safely enclosed and automatically regulates pressure.

With automatic changeover manifolds and alert systems, gas supply continues even when one source is depleted.

Reduces manpower, cylinder transport, and inventory management costs significantly over time.

Centralized systems eliminate the need for cylinder stacking in each department, freeing up valuable space.

Advanced alarm systems, pressure gauges, and digital displays allow for live monitoring and system diagnostics.

Our systems are built to last with corrosion-resistant piping, durable valves, and reliable fittings.

System Components

Here’s what a standard CGDS setup includes:

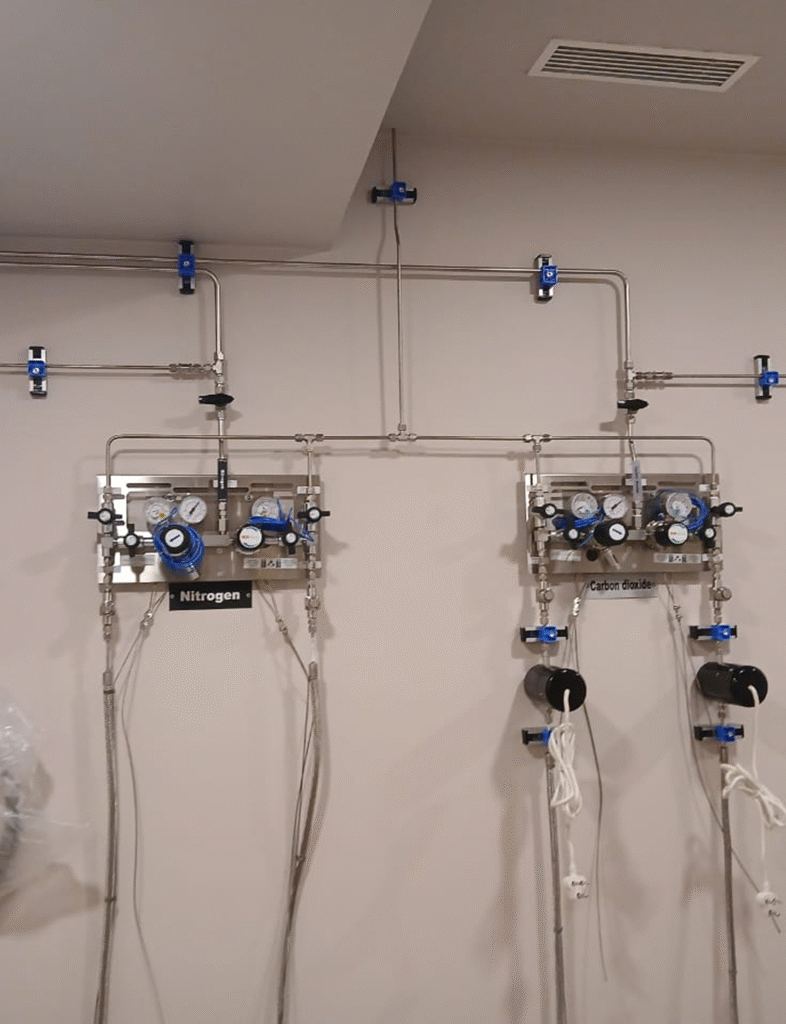

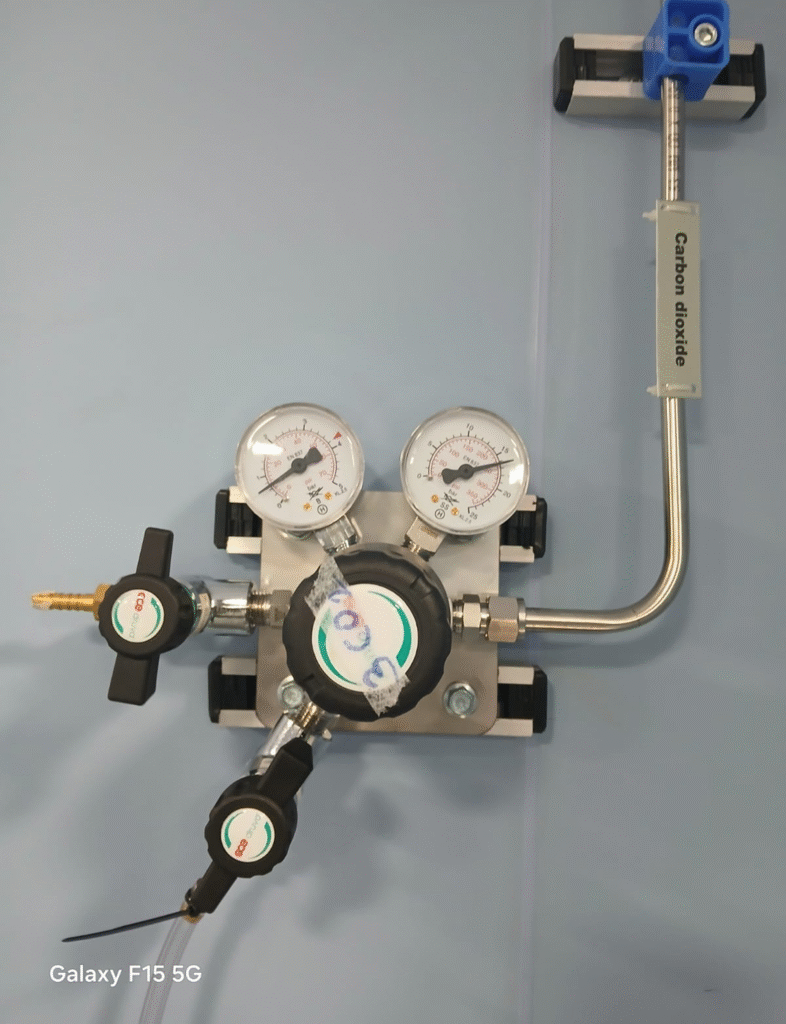

Gas Manifold System

Automatically switches supply from primary to secondary gas cylinders.

Gas Manifold System

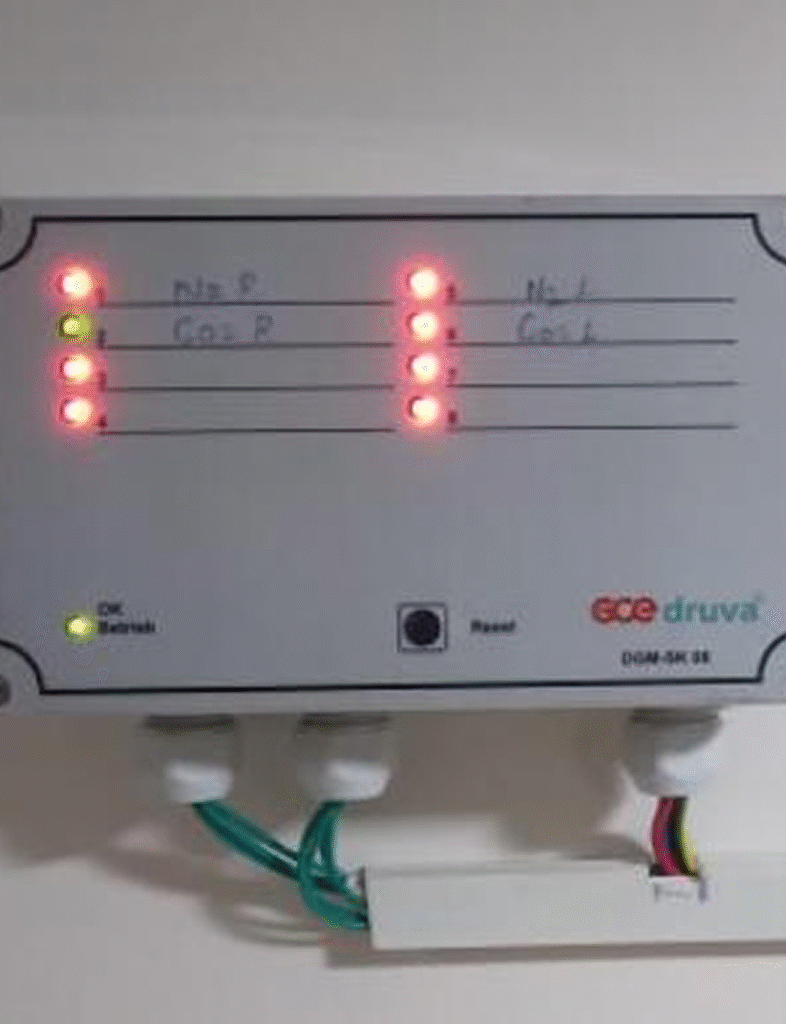

Control Panel

Displays pressure levels, status of gas flow, and alerts in case of faults or low supply.

Control Panel

Medical Gas Pipeline

High-quality copper or stainless-steel pipelines for safe transportation of gases.

Medical Gas Pipeline

Terminal Units

End-use points like outlets in ICU beds, operating theaters, etc.

Terminal Units

Alarms & Safety Devices

Audio-visual alerts for pressure drops, system failures, or leaks.

Alarms & Safety Devices

Pressure Regulators & Valves

Designer

Control flow rate and prevent over-pressurization.

Pressure Regulators & Valves

Designer

Installation Process

We follow a 5-step process to make sure your CGDS is set up perfectly.

Site Inspection & Planning

Understanding your facility layout, gas requirements, and pressure zones.

Design & Engineering

Custom designing a pipeline system that meets local safety standards and international best practices.

Material Selection

Using only certified materials like non-corrosive copper, stainless steel, and durable brass for components.

Installation & Testing

Meticulous pipeline installation with tight sealing and pressure testing.

Training & Handover

Educating your staff on system operation and providing maintenance manuals.

Why Hospitals Trust Our CGDS Solutions?

Support & Maintenance

Our job doesn’t end after installation. We provide

Your Trusted Medical Supply Partner

Premium Surgical Instruments | Reliable Equipment | Medical Gas Pipeline Solutions

Customized for Hospitals, Clinics & Labs – Delivered with Excellence.